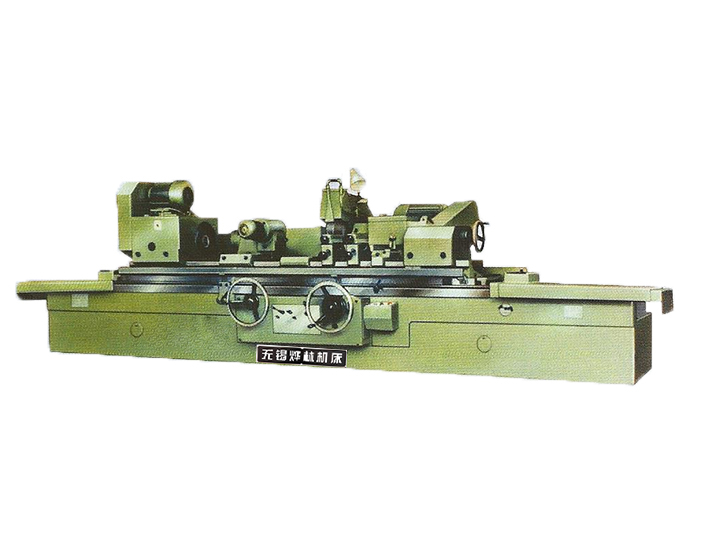

Guideway Grinder: Detailed Explanation of Core Equipment and Application Fields for High-Precision Machining

Release time:2026-04-10 Visits:52

A guideway grinder is a key piece of equipment specifically designed for high-precision planar and straightness machining, widely used in mechanical manufacturing, aerospace, and other fields. Through advanced grinding technology, it ensures that machined surfaces possess extremely high smoothness, precision, and straightness, making it an indispensable tool in modern precision manufacturing.

I. Core Features and Advantages

The core advantages of guideway

grinders lie in their high precision and rigidity. The equipment utilizes high-quality cast iron bed and structural components, subjected to aging treatment to ensure long-term stability. High-precision hydrostatic or rolling guideways serve as motion benchmarks, enabling "precision grinding with precision." The spindle system exhibits minimal vibration, guaranteeing surface machining quality. Additionally, guideway grinders are typically large-scale and heavy-duty, with worktables capable of bearing loads up to several tens of tons, accommodating the machining needs of large workpieces.

Efficient grinding capability is another major feature. The equipment widely adopts heavy-duty grinding technology, paired with high-power spindles and large grinding wheels for efficient metal removal. Automatic wheel dressing and compensation functions maintain the sharpness and shape accuracy of the grinding wheel during machining, ensuring processing consistency.

Advanced numerical control systems are standard in modern guideway grinders. CNC control systems precisely manage multi-axis movements, programmable complex grinding paths, enabling profile grinding and bevel machining. Key accessories include diverse grinding wheels, high-pressure cooling systems, and in-line measurement systems that monitor workpiece dimensions in real-time, achieving closed-loop control to ensure precision.

II. Main Types

Guideway grinders are primarily categorized into gantry-type and floor-type. Gantry-type guideway grinders feature excellent structural rigidity, suitable for machining wide, long, and heavy workpieces. The grinding head moves along the crossbeam, while the worktable performs longitudinal movement. Floor-type guideway grinders lack a moving worktable; instead, the workpiece is fixed to the foundation, and the grinding head moves longitudinally via a gantry or single column. They are ideal for extra-large workpieces such as marine engine bases.

III. Application Fields

Guideway grinders play a crucial role in several key sectors. In mechanical manufacturing, they are the core processing equipment for machine tool guideways, worktable guideways, and slider guideways, directly influencing machine tool precision and performance. In the aerospace sector, they are used to machine high-precision aircraft components and spacecraft guideways, such as landing gear guideways and engine blade mounting guideways, ensuring flight safety.

In the energy equipment field, guideway grinders machine precision guideways and joint surfaces of large components in wind power equipment, hydroelectric generating units, etc. In heavy machinery, they are applied to the machining of critical sliding surfaces in metallurgical equipment, mining machinery, etc. Furthermore, they are used in precision instruments, mold manufacturing, as well as high-precision grinding processes in the automotive parts and construction machinery industries.

IV. Technological Development Trends

Modern guideway grinders are evolving towards numerical control, compounding, intellectualization, and greenization. They integrate automation features such as automatic loading/unloading and robotics, along with intelligent monitoring systems, pursuing higher efficiency, precision, and reliability. Some high-end models are equipped with real-time on-line monitoring and automatic compensation functions to ensure stable machining quality.

In summary, as core equipment for high-precision machining, the technical level and application scope of guideway grinders directly reflect the capabilities of the precision manufacturing sector. Through efficient and intelligent machining methods, they provide reliable precision machining solutions for various industries.