Comprehensive Analysis of Tool Grinders: From Core Functions to Selection Guide

Release time:2026-01-16 Visits:127

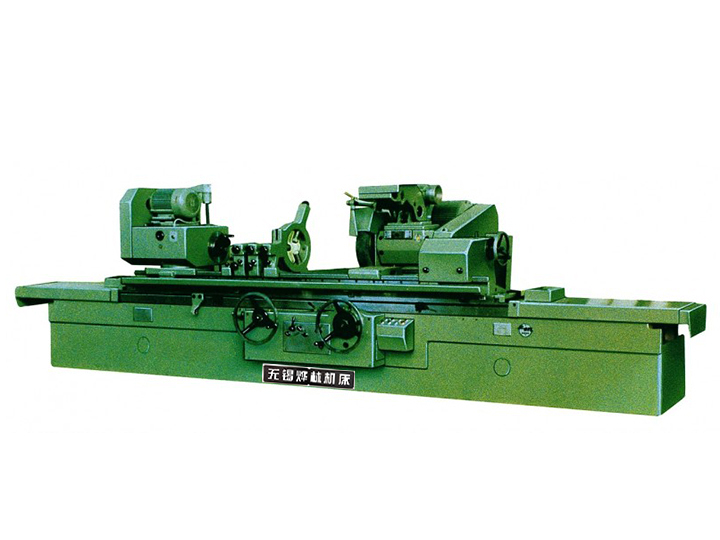

Tool grinders are core equipment in the precision manufacturing field, specifically designed for grinding and dressing various metal cutting tools such as drills, milling cutters, reamers, taps, etc. Different from general-purpose surface or cylindrical grinders, they can efficiently handle the complex geometric shapes and cutting edge requirements of tools, serving as key instruments to enhance manufacturing processing standards.

Core Functions and Features

The core of tool

grinders lies in high precision and flexibility. They support multi-axis linkage (e.g., 4-axis, 5-axis CNC control) to grind complex contours (such as ball heads, arcs, spiral grooves) with repeat positioning accuracy reaching the micrometer level, ensuring tool consistency. Equipped with dedicated fixtures (e.g., centers, dividing heads) and dressing devices (e.g., diamond rollers), these machines are highly versatile—by changing fixtures and programming, they can handle ranging from simple drills to complex formed milling cutters.

Main grinding objects include:

- Drills: Grinding of point angles, chisel edges, and clearance angles;

- End mills: Re-sharpening of end edges, peripheral edges, and ball heads;

- Reamers and taps: Dressing of guide cones, cutting cones, and angles;

- Turning tools: Processing of various insert shapes;

- Special tools: Such as step drills, broaches, etc.

Main Types and Selection Guide

Tool grinders are categorized into manual and CNC types:

- Manual Tool Grinders: Rely on operator experience, with axis movements controlled via handwheels. Advantages include low cost and high flexibility, suitable for small-batch repairs; disadvantages are low efficiency, poor consistency, and extremely high skill requirements.

- CNC Tool Grinders: The mainstream choice in modern manufacturing. Controlled automatically via computer programs, they offer high efficiency, high consistency (programs eliminate human errors), and complex processing capabilities. Integrated in-line measurement systems can automatically compensate for砂轮 wear, but equipment investment and programming maintenance costs are higher.

Key considerations for selection:

1. Processing requirements: CNC models are preferred for mass production or complex tools; manual equipment suffices for simple re-sharpening.

2. Precision requirements: High-precision scenarios (e.g., aerospace, medical devices) must use multi-axis CNC grinders.

3. Budget and skills: CNC equipment requires more capital investment and professional programming personnel.

Application Fields

Tool grinders are the "mother machines" of manufacturing, widely used in:

- Aerospace: Processing high-performance tools for difficult-to-machine materials like superalloys and titanium alloys;

- Automotive industry: Standard and non-standard tools for processing engine and transmission components;

- Mold industry: Ball-end mills and finishing tools required for precision molds;

- Medical devices: Micro-precision tools such as surgical instruments and bone drills;

- General machinery manufacturing: Production and maintenance of daily tools like drills and milling cutters.

Operation and Intelligent Trends

CNC tool grinders rely on CAD/CAM programming software (e.g., NUMROTOplus, ANCA TX) to define processes through 3D models and automatically generate code. Future trends include:

- Automation and Intelligence: Integration of automatic loading/unloading, real-time monitoring, and AI parameter adjustment to improve efficiency;

- Environmental Protection and Energy Saving: Low-energy designs (e.g., linear guide drive systems replacing traditional hydraulics) to reduce carbon emissions;

- High-Precision Development: Nanoscale precision and grinding capabilities for ultra-hard materials (e.g., PCD/CBN) have become competitive focuses.

Technological advancements in tool grinders directly drive the development of manufacturing toward higher precision and efficiency. Rational selection and operational training are crucial to unleashing their potential.