What is a Grinding Machine? In-depth Analysis of Core Equipment for Precision Machining

Release time:2025-12-12 Visits:167

A grinding machine is a type of machine tool that uses a high-speed rotating grinding wheel to perform precision machining on workpiece surfaces. It plays a crucial role in mechanical manufacturing, enabling extremely high dimensional accuracy and excellent surface quality. Unlike traditional machining methods such as lathes and milling machines, grinding machines remove extremely thin layers of material through a micro-cutting process, making them particularly suitable for manufacturing high-hardness materials and precision parts.

The core principle of a grinding machine is based on the numerous abrasive grains on the grinding wheel. These hard and sharp particles perform micro-cutting, scoring, and sliding on the workpiece surface to achieve precision machining. Due to the extremely small size of the abrasive grains, grinding machines can achieve micron-level or even sub-micron-level tolerance control, with surface roughness as low as Ra 0.01μm.

The main characteristics of grinding machines include five key advantages. Firstly, high-precision machining capability to meet the most stringent dimensional requirements. Secondly, excellent surface treatment quality, suitable for applications requiring smooth surfaces. Thirdly, the ability to process high-hardness materials such as hardened steel, cemented carbide, and ceramics. Fourthly, although the cutting force of individual abrasive grains is small, the overall power is relatively large, suitable for high-efficiency production. Finally, grinding machines generate a large amount of heat during processing, so they usually need to be equipped with a cutting fluid system for cooling and lubrication.

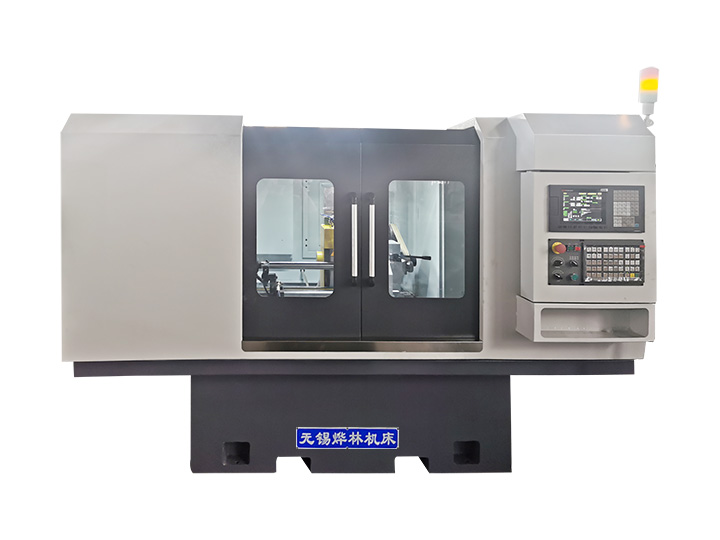

A typical

grinding machine consists of several key components. The bed serves as the basic support structure, ensuring overall stability. The wheel headstock drives the grinding wheel to rotate at high speed, while the workpiece headstock is used for clamping and positioning the workpiece. The worktable provides precise movement control, the feed mechanism ensures machining accuracy, and the cooling system maintains an appropriate operating temperature.

Grinding machines are classified into various types based on different processing requirements. Surface grinders are specifically used for machining flat and formed surfaces, while cylindrical grinders are suitable for processing cylindrical and conical surfaces. Internal grinders focus on precision processing of inner hole surfaces, and centerless grinders are suitable for mass production of shaft parts. Tool grinders are used for grinding and dressing cutting tools, and CNC grinders achieve high-precision machining of complex curved surfaces through computer control.

The grinding wheel is the core tool of a grinding machine, and its performance is determined by the type of abrasive, grain size, hardness, bonding agent, and structure. Common abrasives include aluminum oxide, silicon carbide, CBN, and diamond. To maintain the optimal performance of the grinding wheel, regular dressing operations are necessary to remove dull abrasive grains and blockages. At the same time, the precise balancing of the grinding wheel is also crucial, directly affecting machining quality and equipment safety.

Grinding fluid plays multiple roles in the grinding process. In addition to cooling and lubrication, it can also effectively clean the machining area and prevent rust. Selecting the appropriate grinding fluid can significantly improve machining quality and extend tool life.

In terms of application fields, grinding machines cover almost all precision manufacturing industries. The automotive industry uses them for finishing key engine components, and the aerospace field applies them to the manufacturing of high-performance parts such as turbine blades. The mold industry relies on grinding machines for precision machining of mold cores and cavities, and tool manufacturing requires grinding machines to produce high-precision cutting tools. In addition, bearing manufacturing and precision machinery industries are also important application fields for grinding machines.

In conclusion, as core equipment for precision manufacturing, although grinding machines have a lower material removal rate compared to other machining methods, they have an irreplaceable position in achieving final dimensional accuracy and surface quality. From traditional manual operation to modern CNC technology, grinding machines continue to evolve to meet the growing demand for precision machining. Whether in mass production or single-piece precision machining, grinding machines play a vital role.