In the world of precision machining, the centerless grinder stands out as a critical tool for achieving high-quality finishes and tight tolerances. Unlike traditional cylindrical grinding machines, the centerless grinder offers unique advantages, making it indispensable in various industrial sectors.

| 1. Thru-feed(Special order is required for the bracket used for horizontal feed grinding) | |

| (1) Grinding diameter | 5~80 mm |

| (2) Grinding length | 180mm |

| 2. Plunge feed | |

| (1) Grinding diameter | 5-80mm |

| (2) Grinding length | 140mm |

| 3. Maximum weight of grinding pin workpiece (calculated based on the weight of the workpiece during design) | 4.5Kg |

| 4. Gri.wheel max.spec | P500X150X305 |

| Gri.wheel min.spec | P380×150×305 |

| 5. Reg.wheel max.spec | PSA300×150×127 |

| Reg.wheel min.spec | PSA220×150×127 |

| 6. Gri.wheel speed | 1300 r/min |

| 7. Reg.wheel speed | |

| (1) When processing workpieces | 14-180r/min |

| (2) When repairing the guide wheel | 180r/min |

| 8. Reg.wheel swivel angle | |

| (1) Invertical plane | -2°~5° |

| (2) In horizontal plane | 0°~3° |

| 9. Rotation angle of grinding wheel dresser | ±3° |

| 10. Rotation angle of guide wheel trimmer | |

| (1) Invertical plane | +3° |

| (2) In horizontal plane | -2°~5° |

| 11. Grinding wheel dresser contour height | 20mm |

| 12. Contour height of guide wheel trimmer | 20mm |

| 13. Feed mechanism handwheel feed rate per rotation | 0.5mm |

| 14. Feed mechanism handwheel, soil indexing disc, feed rate per unit rotation | 0.0025mm |

| 15. Cross feed rapid feed rate (when the handle swings 600) | 1mm |

| 16. Feed rate of handwheel perdivision | 0.01mm |

| 17. Hei{ght from centerline of gri.wheel®.wheel to workrest | 210mm |

| 18. Distance between the centerlines of two grinding wheels | |

| (1) Maximum value | 525mm |

| (2) Minimum value | 305mm |

| 19. Toal power of machine | |

| (1) Gri.wheel electomotor | 15KW |

| (2) Reg.wheel electomotor | 1.5KW |

| (3) Hydraulic pump motor | 0.25KW |

| (4) Lubrication pump motor | 0.125KW |

| (5) Cooling pump motor | 0.15K~r |

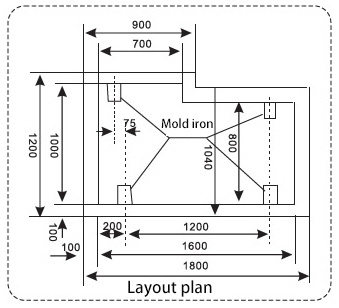

| 20. Overall Size(Length x Width x Height) | 1950×1580×1485mm |

| 21. Net weight | About 3500Kg |

| 22. Machining accuracy | |

| Roundness | 0.002mm |

| Cylindricity | 0.003mm |

| Roughness | Ra0.32μm |