CNC Cylindrical Grinder: The Ultimate Guide to High-Precision Machining and Analysis of Core Advantages

Release time:2026-03-20 Visits:56

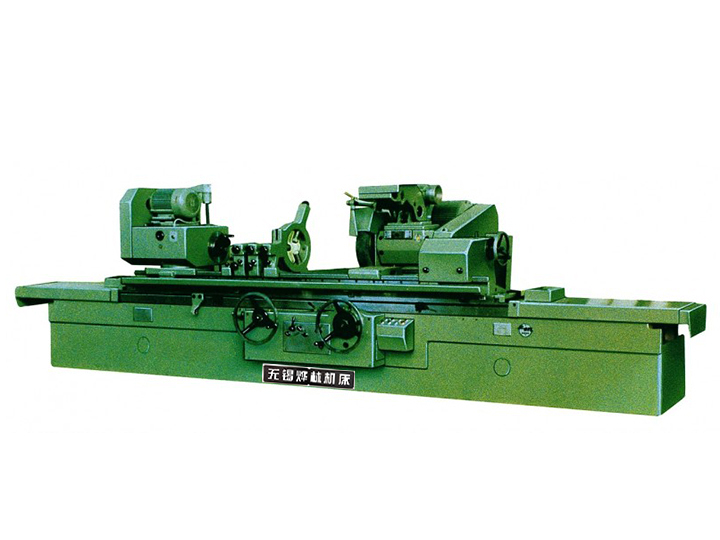

CNC cylindrical grinder is a core equipment in modern precision manufacturing. It realizes automated grinding through a computer numerical control system and is specially used for machining the outer cylindrical surfaces of rotationally symmetric workpieces such as cylindrical and conical shapes. This type of machine tool not only has extremely high precision but also can significantly improve production efficiency, making it an indispensable device in high-end industries such as automotive, aerospace, and precision instruments.

1. Core Structure and Technical Features

CNC cylindrical grinders adopt a mechatronic design, with the main body including a high-rigidity bed, precision wheel head, rotating headstock and tailstock, and a numerical control system. The grinding wheel spindle usually adopts dynamic and static pressure bearing technology to ensure high rotational precision and stability, supporting high-speed grinding (e.g., the linear speed of CBN grinding wheels can reach 80m/s). The machine tool realizes micron-level feed control through two-axis linkage (X/Z axis) servo drive, with a minimum resolution of 0.001mm. At the same time, the equipment integrates a cooling system and fully enclosed protection, ensuring both machining quality and compliance with safety and environmental protection requirements.

2. Core Advantages and Application Value

2.1 Ultra-high Precision and Stability: The CNC system, combined with online measuring devices (such as active gauges), can real-time monitor workpiece dimensions and automatically compensate for grinding wheel wear. The dimensional dispersion of batch processing can be controlled within 0.003mm, and the surface roughness can reach below Ra0.32μm.

2.2 Efficient Automated Production: Supports automatic grinding wheel dressing, programmed grinding cycles (rough grinding, fine grinding, spark-out) and fault self-diagnosis functions, reducing manual intervention. Production efficiency is 30%-50% higher than traditional grinders.

2.3 Strong Flexible Machining Capacity: By modifying the program, it can adapt to multi-variety, small-batch production, suitable for grinding the outer circle, conical surface and complex curved surfaces of shaft and disc parts.

2.4 Low Operational Dependence: The graphical CNC interface simplifies parameter setting, reduces requirements for operators' skills, and supports one-person multi-machine management.

3. Typical Application Scenarios

CNC cylindrical grinders are widely used in high-precision parts manufacturing, such as:

- Automotive engine crankshafts, gearbox shaft parts

- Aerospace engine rotors, landing gear actuators

- Precision machine tool spindles, ball screws

- Hydraulic piston rods and energy industry rotor shafts

4. Selection and Usage Suggestions

When selecting a model, focus should be on the maximum grinding diameter/length, CNC system functions, precision indicators (such as roundness, cylindricity) and automation configuration (such as automatic loading and unloading). Daily maintenance requires keeping the machine tool clean, regularly checking the coolant and grinding wheel status to ensure long-term stable operation.

Conclusion: CNC cylindrical grinders have core advantages of high precision, high automation and high stability. Although the initial investment is relatively high, their value in improving product quality and reducing production costs is significant, making them key technical equipment for promoting the upgrading of the precision manufacturing industry.