Comprehensive Analysis of Crankshaft Grinders: From Principles to Applications, Understanding Core Manufacturing Equipment in One Article

Release time:2026-01-23 Visits:145

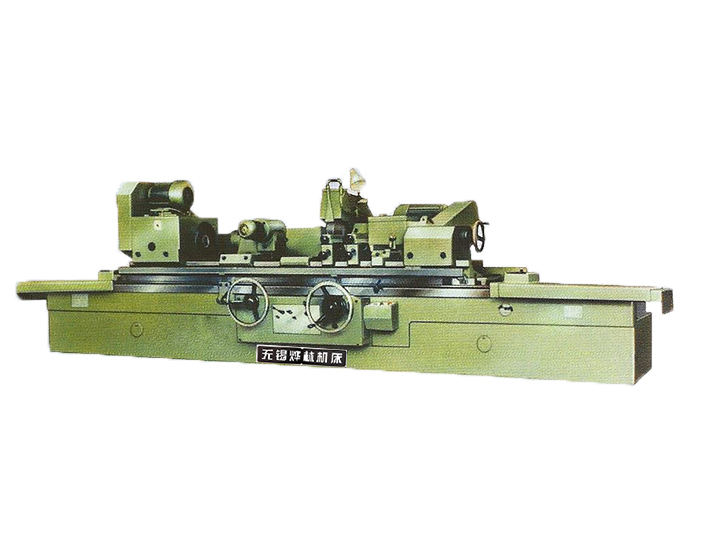

Crankshaft grinders are indispensable high-precision CNC machine tools in engine production lines, specifically designed for precision grinding of the main journals and connecting rod journals of crankshafts. By strictly controlling dimensional accuracy, geometric shape, and surface roughness, they ensure engines possess high power, low vibration, and long service life. Ordinary cylindrical grinders cannot meet the special structure and extremely high precision requirements of crankshafts, thus making crankshaft grinders key equipment for processing core engine components.

Core Structure and Working Principle

Crankshaft grinders consist of core components such as the bed, headstock and tailstock, grinding wheel headstock, synchronous fixtures, and CNC system. Their working principle is based on high-precision servo control: the headstock drives the crankshaft to rotate, and the synchronous fixture adjusts its position in real-time through electronic synchronization technology to ensure the eccentric connecting rod journal maintains the correct relative position with the grinding wheel. The in-line measurement system monitors dimensional data in real-time and feeds it back to the CNC system for automatic compensation, ensuring processing consistency.

Technical Advantages and Application Value

Crankshaft

grinders have three major advantages: high precision (micron-level tolerance), high efficiency (automated loading and unloading), and high flexibility (multi-model adaptation). They support constant linear speed grinding technology, which automatically adjusts the grinding wheel speed according to the crankshaft position to ensure stable grinding force, significantly improving surface quality. In addition, the intelligent operation interface and modular design reduce operational difficulty and maintenance costs, helping enterprises achieve continuous and stable production.

Maintenance and Operation Specifications

To ensure long-term stable operation of the equipment, it is necessary to regularly inspect the lubrication system, fasten key components, and calibrate the measurement system. Operators need to be familiar with equipment performance and strictly follow the procedures: check the status of handles and travel stops before starting the machine, and lubricating oil according to specifications; monitor parameter abnormalities during processing and adjust the grinding program in a timely manner. Daily maintenance includes coolant replacement, grinding wheel dressing, and guide rail cleaning to extend equipment life and ensure processing accuracy.

Crankshaft grinders are a technical benchmark in high-end manufacturing, and their development level directly reflects a country's strength in industrial fields such as automotive and marine. With the advancement of intelligent manufacturing, crankshaft grinders will further integrate data interconnection and adaptive control functions, providing core support for modern industry.