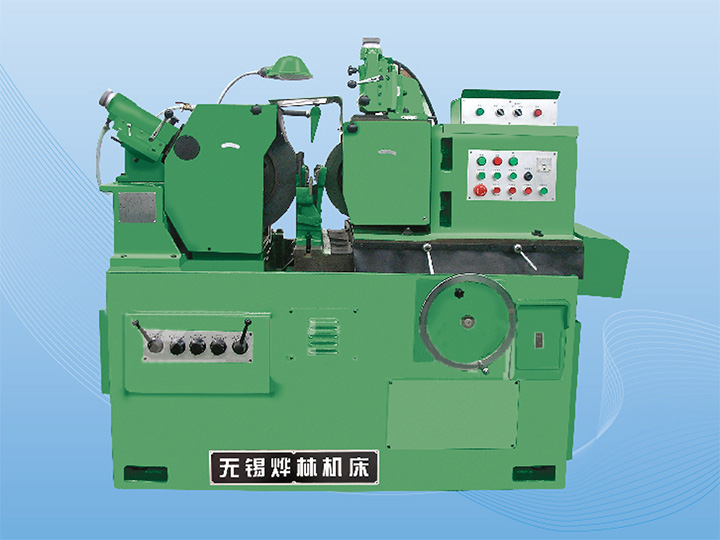

Complete Guide to Centerless Grinders: Principles, Advantages, and Application Analysis

Release time:2025-12-26 Visits:167

Centerless grinders are high-precision grinding machines specifically designed for processing the outer cylindrical surfaces of workpieces, such as shafts, sleeves, and piston rings. Their core feature is that they do not require centers or chucks to fix the workpiece center, hence the name "centerless". This design not only improves processing efficiency but also significantly enhances the precision and consistency of the workpiece. This article will comprehensively analyze the working principle, main types, advantages and limitations, as well as application fields of centerless grinders to help you gain an in-depth understanding of this important manufacturing equipment.

The working principle of a centerless grinder is based on three key components: the grinding wheel, the regulating wheel, and the workpiece rest blade. The grinding wheel is a high-speed rotating wheel responsible for material removal; the regulating wheel rotates at a slower speed, driving the workpiece to rotate through friction and controlling its rotational speed and feed rate; the workpiece rest blade supports the workpiece, ensuring it is in the correct grinding position. By tilting the regulating wheel at an angle (usually 1-5 degrees), the workpiece achieves axial feed while rotating, thereby completing the grinding process. This design makes centerless grinders particularly suitable for high-volume continuous production.

There are two main grinding methods for centerless grinders: through-feed grinding and in-feed grinding. Through-feed grinding achieves automatic workpiece feeding through the tilt of the regulating wheel, suitable for efficient processing of long bar workpieces, such as piston rods and guide shafts. In-feed grinding, on the other hand, grinds specific parts of the workpiece through radial movement of the grinding wheel or regulating wheel, suitable for processing parts with shoulders or complex shapes, such as gears and bearing raceways. These two methods each have their own advantages and can be selected according to specific production requirements.

Centerless grinders offer significant advantages. Firstly, their high efficiency makes them the preferred choice for mass production, eliminating the need for frequent workpiece clamping and greatly improving production efficiency. Secondly, by avoiding clamping errors, workpieces can achieve extremely high roundness, cylindricity, and dimensional consistency. In addition, centerless grinders are easy to integrate into automated production lines, with simple operation, reducing technical requirements for operators. However, centerless grinders also have some limitations. Initial setup is complex and requires experienced technicians for adjustment, and they are not suitable for processing discontinuous surfaces or parts with large planar bosses. Improper setup may also result in roundness errors.

In terms of application fields, centerless grinders are widely used in the automotive industry, bearing manufacturing, hydraulic and pneumatic industry, aerospace, and general machinery manufacturing. For example, piston rods and valve lifters in automobiles, rolling elements in bearings, valve spools and guide sleeves in hydraulic systems all rely on the high-precision processing of centerless grinders. With the development of technology, centerless grinders are evolving towards intelligence and high efficiency, providing stronger support for modern manufacturing.

In conclusion, with their unique working principle and significant advantages, centerless grinders have become the ideal choice for high-precision cylindrical workpiece processing. Despite limitations such as complex setup and limited applicability, their performance in efficiency, precision, and automation makes them indispensable in industrial production. For enterprises seeking high-quality and large-scale production, centerless grinders are undoubtedly a key equipment worth investing in.