Centerless grinding machine features of machine tools

1. The grinding wheel spindle bearing is a five piece dynamic pressure sliding bearing with high load-bearing capacity and stiffness;

2. The main shaft bearing of the guide wheel is a 1:30 integral sliding bearing with high load-bearing capacity and precision;

3. The guide wheel frame can rotate at a small angle in the horizontal direction. When grinding workpieces with small taper angles, the grinding wheel does not have to be tapered, which improves the utilization rate of the grinding wheel and reduces the dressing time;

4. The variable speed of the guide wheel adopts AC frequency speed regulation, which can achieve infinite adjustment;

5. The sand and guide wheel trimmers are both driven back and forth by hydraulic transmission, with infinite adjustment;

6. Equipped with an automatic cutting and grinding device, capable of semi-automatic cyclic operation;

7. The grinding wheel spindle can be equipped with a ceramic spindle.

Centerless grinder purpose and scope of application

This machine tool can be used for centerless through grinding of various cylindrical parts, annular parts, and long bar materials. It is also suitable for cutting in and grinding of cones with a circular dimension less than 1:20 and various formed rotary parts. It is suitable for batch and mass production needs.

Centerless grinding machine parameter specifications

|

1. Thru-feed |

|

|

(1) Grinding diameter |

10—100mm |

|

( 2) Grinding length |

210mm |

|

2. Plunge feed |

|

|

(1) Grinding diameter |

10~100mm |

|

(2) Grinding length |

195mm |

|

3. Gri.wheel spec |

P500×200×305 |

|

4. Reg.wheel spec |

PDA350×200×203 |

|

5. Gri.wheel speed |

1250r/min |

|

6. Reg.wheel speed |

|

|

(1) Working Time |

10-200r/min (stepless) |

|

(2) Repair Time |

200r/min |

|

7. Reg.wheel swivel angle |

|

|

(1) Invertical plane |

-2°~5° |

|

(2) In horizontal plane |

0°~3° |

|

8. Feed rate ofhandwheel perdivision |

0.002mm |

|

9. Dressing device graduation |

0.01mm |

|

10. Height from centerline of gri.wheel®.wheel to workrest |

255mm |

|

11. Toaf power of machine |

21.66KW |

|

(1) Gri.wheel electomoto |

18.5KW |

|

(2) Reg.wheel electomotor |

2.2KW |

|

12. Power supply |

Three phase 380V 50HZ |

|

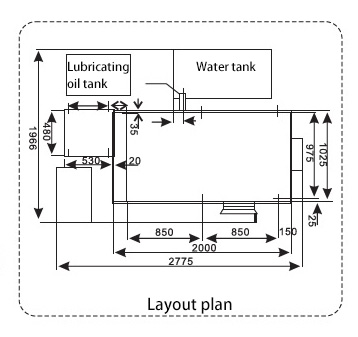

13. Overali dimensions |

2675×1505x1615mm |

|

14. Machine weight |

About 4500kg |

|

15. Machining accuracy |

|

|

Roundness |

0.002mm |

|

Cylindricity |

0.003mm |

|

Surface roughness ra |

Ra0.32μm |