Centerless grinding main features of machine tools

1. The layout of the machine tool adopts a single-sided movement method of the guide wheel frame;

2. The grinding wheel shaft is a suspended structure, and multi piece dynamic pressure bearings are used for both front and rear supports. The main shaft adopts ceramic plating technology, which has good rigidity and can adapt to the needs of heavy load grinding and precision grinding;

3. The guide wheel shaft adopts a double support structure, with rolling bearings used for both front and rear supports. The shampoo has good rigidity;

4. Adopting Mitsubishi servo control system, manual adjustment, trimming and compensation can be completed. Automatic work cycle control, with high reliability and fault self diagnosis, using touch screen human-machine interface, easy to operate;

5. The feed mechanism is driven by AC servo electric drive, and the grinding wheel dressing and compensation motion are driven by stepper electric drive;

6. The feed guide wheel adopts a double V-shaped pre tensioned rolling guide rail, which is sensitive to feed;

7. The speed regulation of the guide wheel adopts AC variable frequency infinite adjustment;

8. Users can choose a balancing device (special order) to automatically balance the grinding wheel.

Centerless grinding main purpose and scope of application

This machine tool is suitable for centerless through grinding of various cylindrical and annular parts, as well as element center cutting grinding of conical and formed rotary parts with cone angles less than 3 degrees. It is suitable for mass production.

Centerless grinding parameter specifications

|

1. Grinding workpiece diameter |

5~80mm |

|

2. Thru-feed(Standard bracket) |

200mm |

|

2. Plunge feed |

145mm |

|

3. Gri.wheel spec |

PSA500×150×305mm |

|

4. Reg.wheel spec |

PSA300×150×177.8mm |

|

5. Gri.wheel speed |

1650r/min (line speed 45m/s) |

|

6. Regulating wheel speed(stepless) |

12~200r/min |

|

7. Reg.wheel swivel angle |

|

|

(1) Invertical plane |

-2°~5° |

|

(2) In horizontal plane |

0°~3° |

|

8. Axial displacement adjustment of guide wheel |

±5mm |

|

9. Minimum feed value of guide wheel frame |

0.001mm |

|

10. Minimum feed value of grinding wheel dresser |

0.001mm |

|

11. Minimum feed value of guide wheel trimmer |

0.01mm |

|

12. Rotation angle of the guide wheel conditioner in the horizontal plane |

-2°~7° |

|

13. Adjustment amount of diamond drill position for guide wheel dresser |

±15mm |

|

14. Height from centerline of gri.wheel®.wheel to workrest |

200mm |

|

15. Toal power of machine |

20.96KW |

|

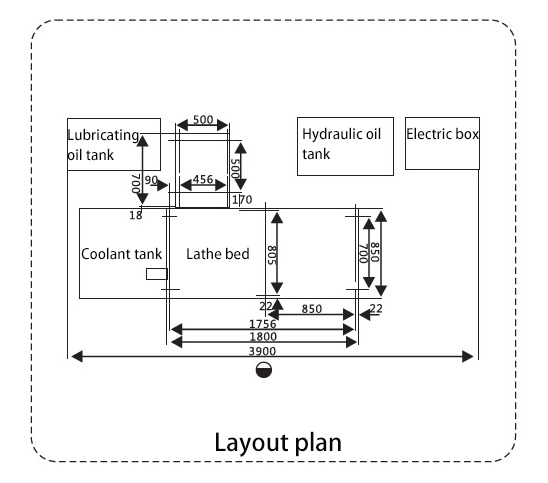

16. Overall dimensions(Excluding electrical box, water tank, lubricating oil tank) |

2675×1505×1615mm |

|

17. Machine weight |

About 5000Kg |

|

18. Machimng accuracy |

Standard specimen c20X90mm, 45 # steel |

|

Roundness |

0.001mm |

|

Cylindricity |

0.002mm |

|

Surface Roughness Ra |

Ra0.16um |